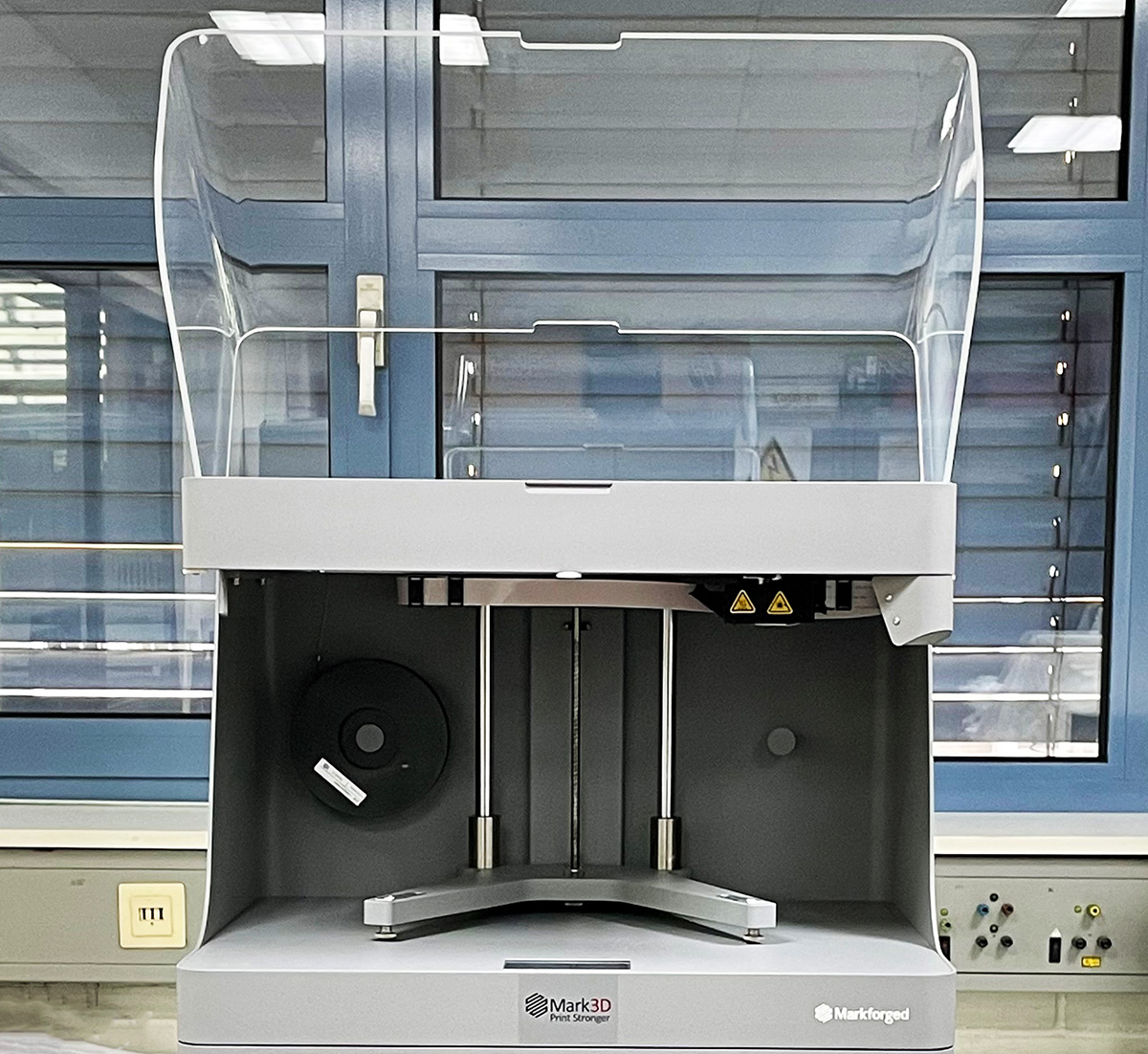

Rapid prototyping & 3D printing

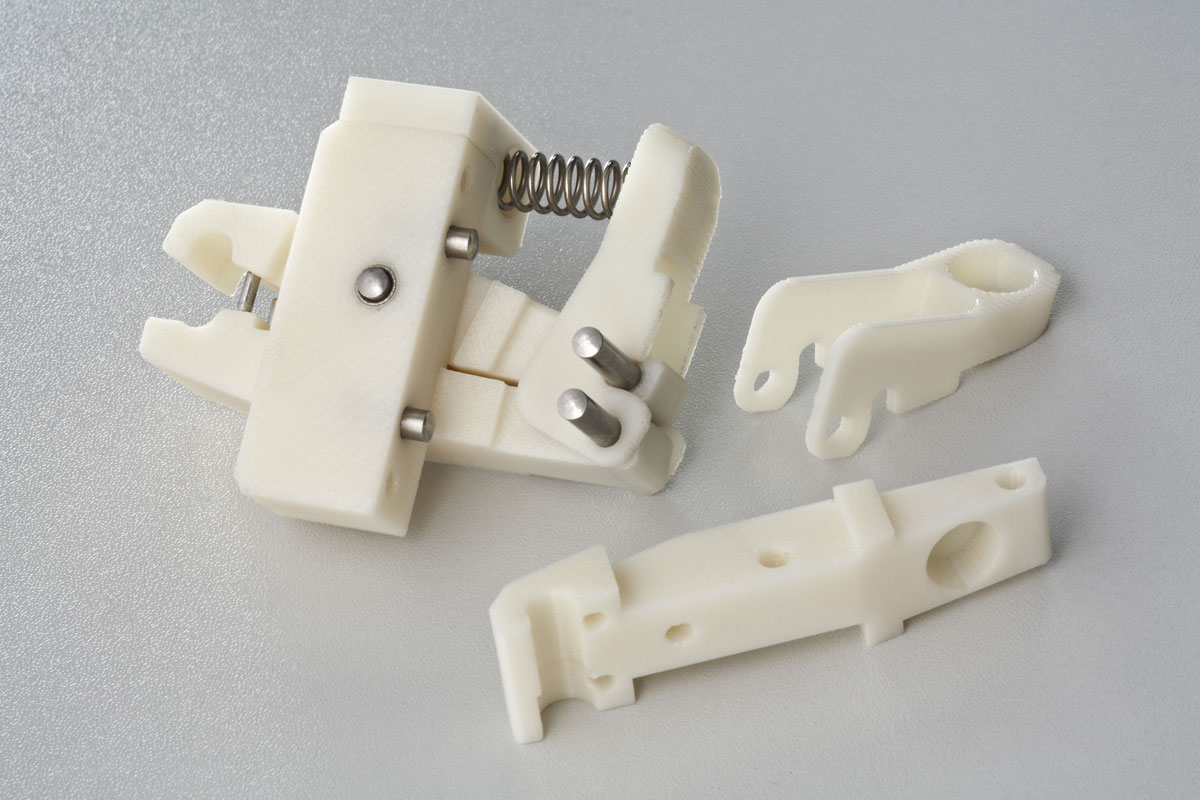

Individual parts

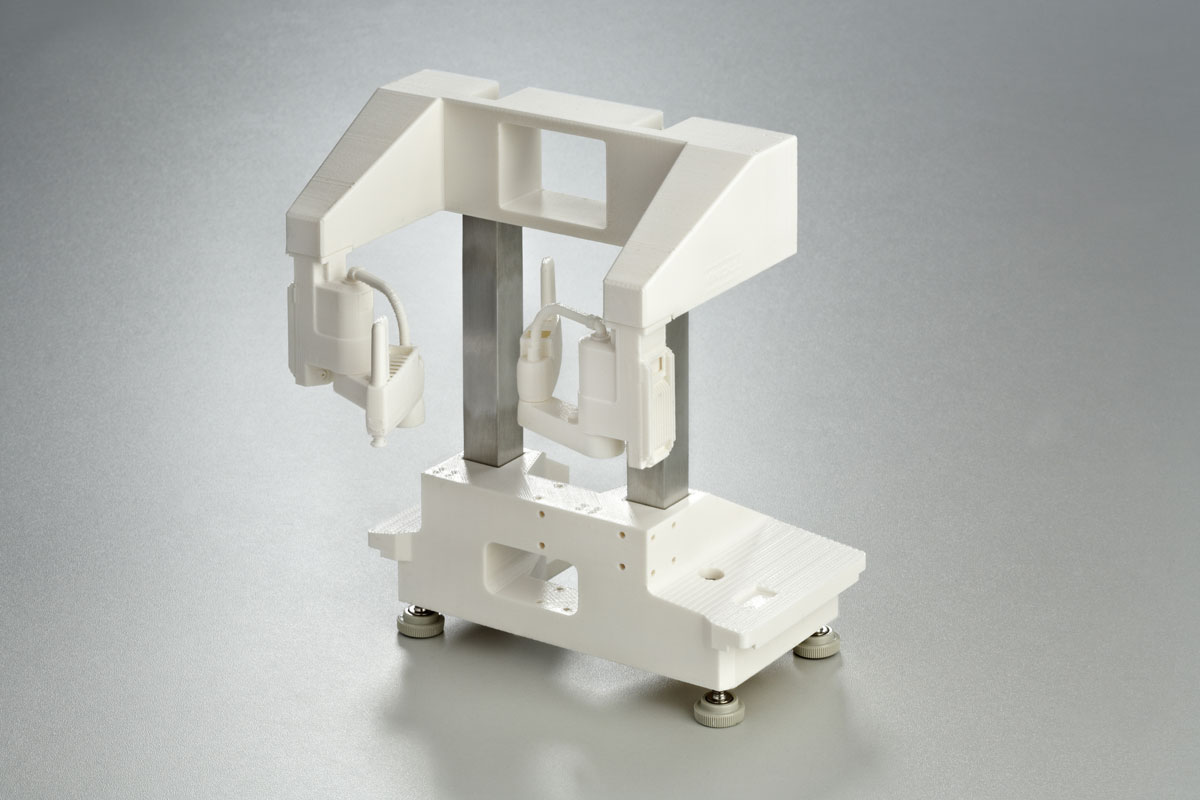

But rapid prototyping is also a powerful tool for customer presentation purposes: the data is transferred directly from CAD, so that a component true to the original can be produced in the shortest possible time. The high level of precision in production also allows the production of complete assemblies.

Your advantages

*All internal departments – Design & Development, Mechanical Manufacturing, Control Cabinet Construction, Water Jet Cutting and Rapid Prototyping – can also be individually called upon to carry out external orders.

Further possibilities

Optimisation through special post-treatment

Examples & technical specifications

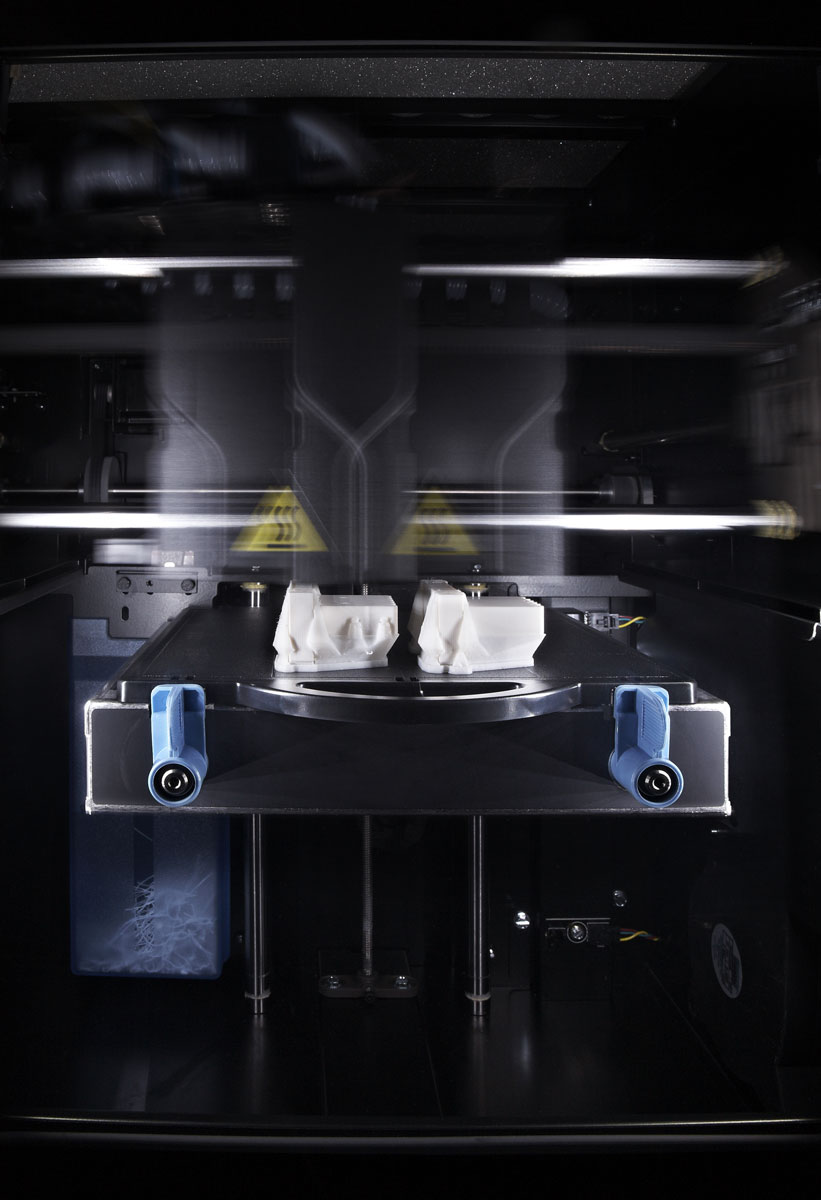

3 dimensional components

Requirements

Maximum part size:

203 x 203 x 152 mm

Scalable when joining several components together

Accuracy:

0,05

Minimum wall thickness:

1 mm

Preconditions

Required data:

.stl file (via e-mail)

Required stability:

stable, medium, light

Required colour:

ivory, black, red, white

(others on request)

Please indicate any special requirements for the component