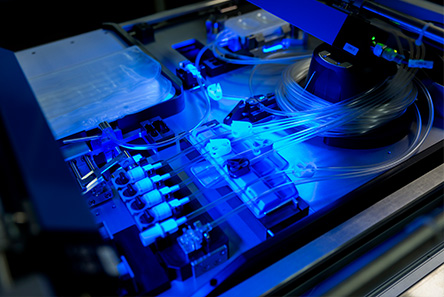

Connection technology

Coiled or assembled

Our connection technologies enable us to realise “tube to tube” or “tube to component” connections.

The tubes can be processed in a coiled or assembled state. Depending on the material and components, the connection is made using solvents or high-frequency/ultrasonic technology. In ultrasonic technology, we use welding generators of all well-known manufacturers according to best suitability or according to customer requirements.

The tubes can be processed in a coiled or assembled state. Depending on the material and components, the connection is made using solvents or high-frequency/ultrasonic technology. In ultrasonic technology, we use welding generators of all well-known manufacturers according to best suitability or according to customer requirements.

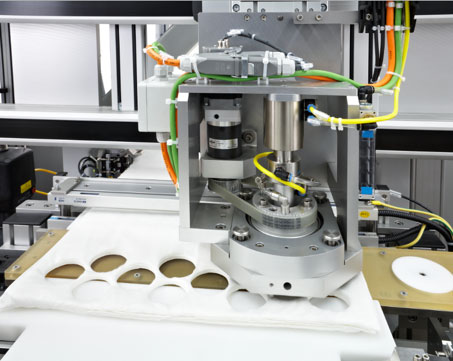

Separation technology

The right cut for each material

The following technologies are used to separate and cut a wide variety of materials such as cellulose, non-wovens, PVC or PE:

Knife cutting, wobble cutting, rotary cutting, punching, ultrasonic and laser cutting.

Knife cutting, wobble cutting, rotary cutting, punching, ultrasonic and laser cutting.

We also use our specially developed cutting head based on “Spin-Cut” technology.

Cutting

We use different cutting methods to cut a wide variety of materials.

Bonding

We bond by using solvents with process-safe in-house dosing technology.

Welding

We use different welding methods such as high-frequency, ultrasonic or thermal welding.

Connection & Separation Technologies

You are looking for a partner

to help you with your project?

Benefit from our experience now and contact us.