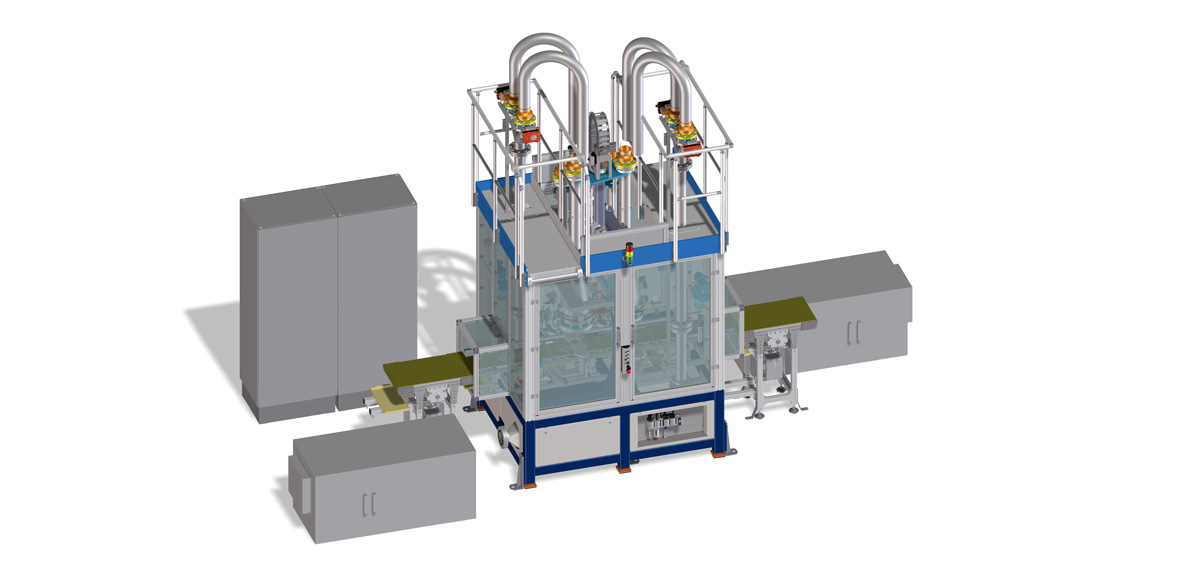

The following features were successfully implemented in the system

- Quick-change mechanism for workpiece pick-up

- Wide variety in shape and size of catalytic converters

- Impact protection in parts handling to prevent damage to the system and product

- Bad parts are detected and sorted out

- All drives are servo-controlled (electrically or pneumatically actuated)

- Low vibration during testing

- Robustness against dusty environments

- Easy access for maintenance to components such as filters, tools and actuators Umgebung