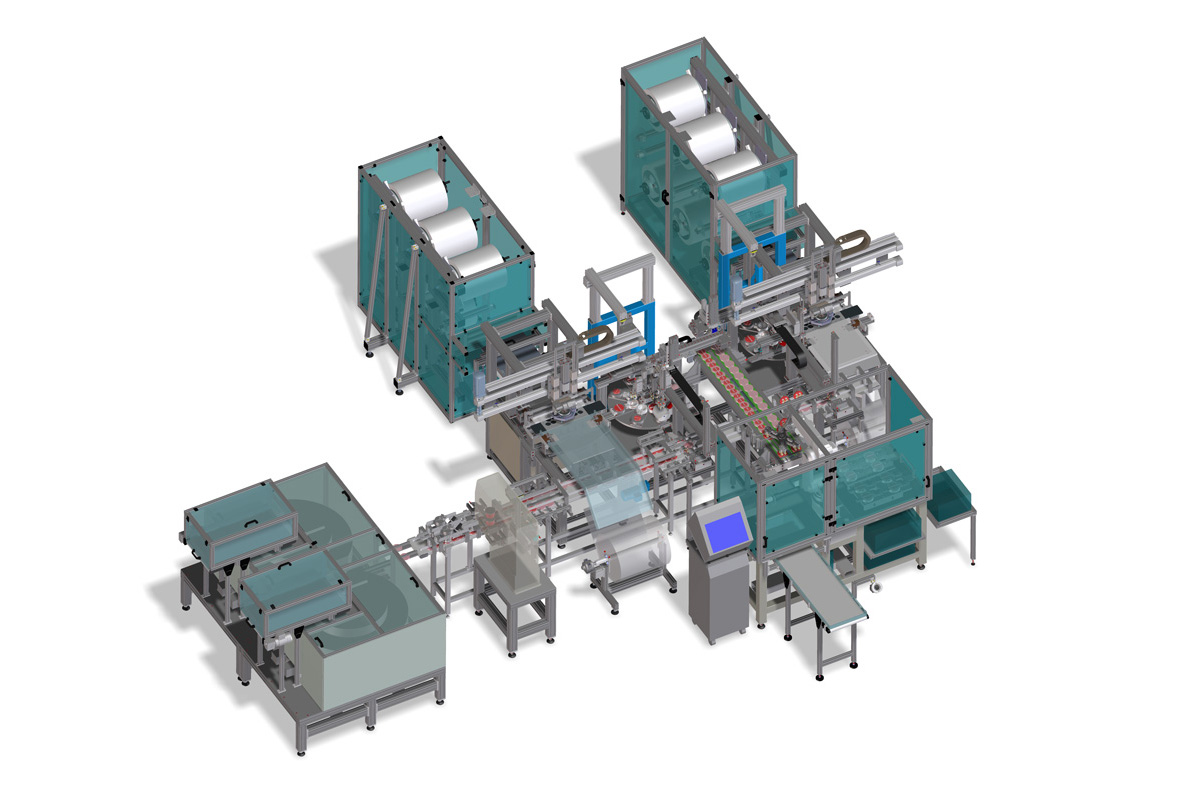

Modules

- 100% testing of blood filters via leak test

- Successfully tested products are marked with a laser inscription

- Two independent unwinding and cutting stations for the filter fleece

- Automatic conveying and feeding unit for the housing parts

- Tampon printing station for marking the filter types

- Ultrasonic welding unit

- Automatic print test station with integrated laser marking